Agua Dulce

Benefits of Sulfur Burners:

- Most plants require a specific pH in order to grow properly.

- Treating untreated water with a sulfur burner drops the pH instantly

- Lowering the pH with acid will reduce the bicarbonates.

Benefits of Breaking Down Bicarbonates:

- Bicarbonates (HCO3) bond with calcium and other elements in the water and soil. This bond ties up beneficial elements so they are no longer available to the plants.

- Using acid to neutralize the bicarbonates in the water, helps free up the minerals and nutrients in the water.

- Bicarbonates tie up the nutrients in the water and are not allowing them to be utilized when the irrigation water hits the soil. This is why you see a lot of times the water sitting on top of the soil and not going deeper to the roots.

Purposes of the Technology:

Through the Sweetwater Solution™ (more commonly known as the Sweetwater sulfur burner), the sulfur burner generates sulfurous acid in order to provide the most efficient, simple, safe, and affordable solution to a series of water and soil condition.

The Science of the Agua Dulce Sulfur Burners:

The Problem: Water and soil conditions with high pH level as well as bound-up salts or sodium concentrations. Alkaline water and soil accompanied by high levels of carbonates and bicarbonates.

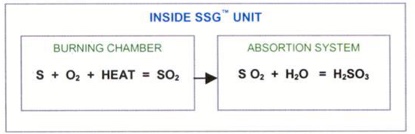

The Solution: The Sulfur Burner, (which burns elemental sulfur), blends SO2 gas with raw alkaline water, creating a mild solution of sulfurous acid which can lower water pH levels.

Oxidized sulfur creates SO2 gas. The SO2 gas is blended with water to create sulfurous acid (H2SO3). Often times, when diluted with irrigation water, the Sulfurous acid seeks out a dissolved oxygen molecule and creates H2SO4.

The Result: Bicarbonates (HCO3) are often present in irrigation water that is alkali in nature. If the water is acidified using the SS™-10, the bicarbonates will be neutralized.

MODELS

SW 250

- Hopper Capacity: 400lbs elemental prill sulfur

- Burn Rate: 5-10 lbs. of sulfur per hour

- Treats 100-200 GPM

SW 500

- Hopper Capacity: 500lbs elemental prill sulfur

- Burn Rate: 7-13 lbs per hour

- Treats 600-1400 GPM

- Minimum of 20 psi and maximum of 40 psi

- Dimensions: 48Wx34Dx71H

SW 1000

- Hopper Capacity: 1700lbs elemental prill sulfur

- Burn Rate: 10-20 lbs per hour

- Treats: 1200-3000 GPM

- Minimum 30PSI and maximum 45 PSI

- Dimensions: 60Wx48Dx71H

SW2000

- Hopper capacity: 2500lbs elemental prill sulfur

- Burn Rate: 40-55 lbs per hour

- Treats 3000- 6000 GPM

- Minimum of 30psi and maximum 0f 45psi

- Dimensions: 60W x 48D x 76H

EO250

- Hopper Capacity:

- Burn Rate:

- Treats:

- Run at 25 PSI

- Dimensions: 48W x 36D x 54H

Examples of Sulfur Burners